Casting Capabilities

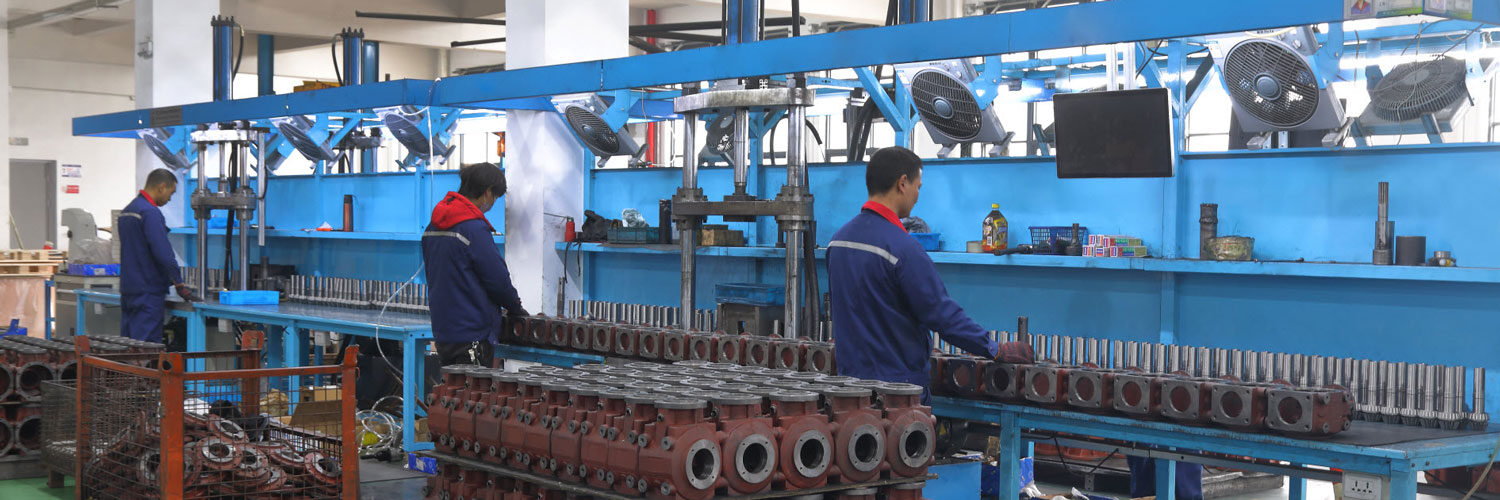

At Worldwide Sourcing and Solutions, we specialize in casting parts using a variety of materials, including iron, steel, and aluminum alloys. Our experienced technicians and state-of-the-art equipment allow us to produce high-quality, precise castings that meet the unique requirements of each project.

One of our key strengths is our ability to produce complex castings, such as cast pipe and high-pressure castings. These parts require specialized knowledge and equipment to ensure that they meet the required specifications for strength and durability. Our team of experts produces castings that match or surpass even the most challenging specifications.

Worldwide Sourcing and Solutions specializes in producing smaller, more intricate parts using sand casting, investment casting, and die casting processes. We work closely with our clients to understand their specific needs and provide customized solutions. Our commitment to quality and precision ensures that every casting we produce satisfies the highest standards of performance and reliability.

Contact us today to learn more about our casting capabilities and how we can assist with your next project.

CAST PIPE

- Weight 20 lbs to 55lbs.

- 8 Finished items

- Tight tolerance machining. True positions.

- Customer redesigned fabricated version to complete machined part.

- Difficult casting, 80% savings to US. Machining added additional savings.

HIGH PRESSURE CASTINGS

- Weight 3lbs to 14lbs.

- 40 Finished items made from 8 castings.

- Customer performs all low and medium volume in house.

- Tested for Hydraulic Pressure, with less than 100ppm fall out.

- Customer savings 40%. Offered blended pricing to customer. Average Finished price $12 to customer. Gave 15% reduction to customer, retained work, and increased margin.