Manufacturing Services

At Worldwide Sourcing and Solutions, we are committed to providing our clients with high-quality manufacturing services. We understand that the manufacturing process is a crucial part of the overall product development process, and we take great care to ensure that our products are manufactured to the highest quality standards. Here’s an overview of our manufacturing process:

Step 1: Materials Procurement

The first step in the manufacturing process is to procure the necessary materials. We work with a network of trusted suppliers to source high-quality raw materials, ensuring that your products are manufactured to the highest standards.

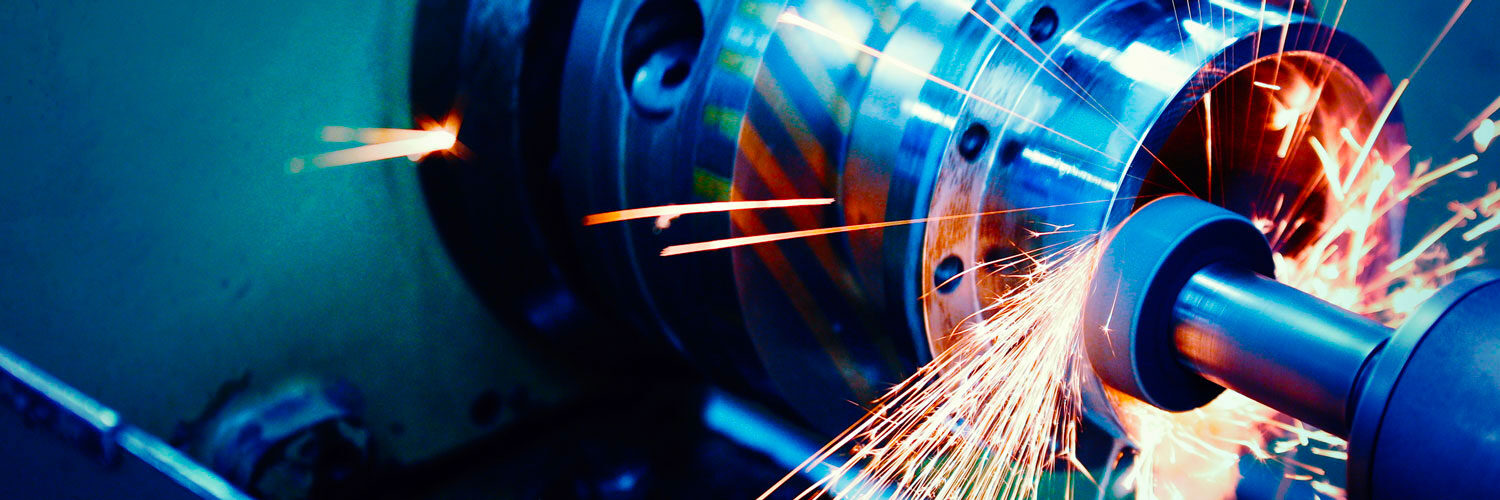

Step 2: Machining and Fabrication

Once we have procured the necessary materials, our skilled machinists and fabricators use state-of-the-art equipment to shape and form the raw materials into the desired product. Our dedicated team of engineers has years of experience working with a wide variety of materials and manufacturing methods, and we use the best practices to ensure that your products are of the highest quality.

Step 3: Quality Control

Quality control is a crucial part of the manufacturing process. We have a dedicated team of quality control engineers that uses a variety of methods to ensure that our products meet or exceed our customers’ specifications and requirements. We adhere to stringent ISO 9001 standards covering a wide range of areas, including customer satisfaction, management responsibility, and continuous improvement. If our customers have established a specific set of quality control processes, we guarantee meeting those standards.

Step 4: Assembly and Testing

After the product is machined and fabricated, our manufacturing team will assemble the product, which then undergoes rigorous testing to ensure that it meets all required specifications and standards. Our testing processes include visual inspection, functional testing, and stress testing to ensure that the product can withstand real-world use.

Step 5: Packaging and Shipping

Once the product has passed all quality control checks and testing, our team carefully packages the product to ensure that it arrives at its destination in perfect condition. We work with a variety of shipping companies to provide our clients with the best shipping options, including global shipping options, ensuring timely and cost-effective delivery.