High-Accuracy Components for Complex Applications

Worldwide Sourcing & Solutions (WSS) is a premier provider of high-accuracy machining services, utilizing state-of-the-art equipment and highly skilled technicians to produce top-tier parts. Whether you need complex geometries for aerospace or heavy-duty components for industrial machinery, our facilities deliver exceptional consistency and dimensional integrity.

We handle the full spectrum of production – from rapid prototyping in our U.S. facilities to high-volume production runs through our global network – working with a variety of materials, from metals to plastics and composites.

Our Machining Capabilities & Equipment

Our facilities use a comprehensive range of CNC machines to offer conventional machining services like milling, boring, drilling, tapping, and grinding. We have the technology to machine larger parts and more complex shapes with ease.

Advanced CNC Equipment

Our shop floor is equipped to handle diverse geometries and tolerances:

- Vertical and Horizontal Mills: We utilize advanced milling centers to shape complex parts with speed and exactitude.

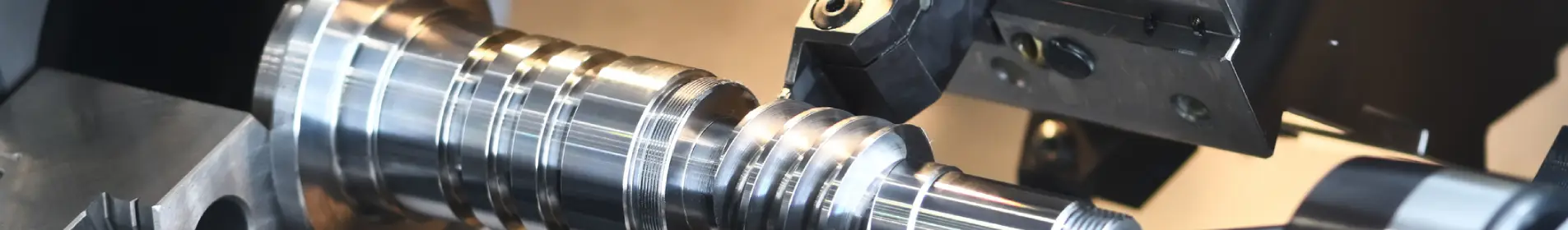

- Lathes: Our turning capabilities allow for the production of cylindrical parts with superior concentricity and surface finish quality.

- 4th and 5th Axis Capabilities: We employ multi-axis machining to produce complex shapes in a single setup, reducing handling time and ensuring exacting standards.

Large Part Capacity

Unlike many standard shops, our horizontal CNC machines offer the ability to handle significant component sizes:

- Maximum Dimensions: We can machine parts up to 70″ long, 40″ wide, and 40″ tall.

- Complex Geometries: This large capacity, combined with multi-axis control, allows us to machine large rings, structural housings, and complex castings that other suppliers cannot handle.

Machining Examples: Versatility in Action

Our versatile engineering and production capabilities allow for an array of CNC machined parts. Below are examples of common components we manufacture.

Brackets & Structural Mounts

- Weight Range: ½ lbs to 65 lbs.

- Materials: We machine brackets from all material types, including steel, aluminum, and iron.

- Application: These tight-tolerance brackets are critical for structural integrity in heavy equipment and automotive assemblies.

Stainless Steel Components

- Weight Range: ½ lbs to 15 lbs.

- Materials: We work with various stainless steel grades (304, 316, etc.) known for machining difficulty.

- Complexity: We produce complex castings and large rings that require strict adherence to specifications and superior surface finishes for corrosion resistance.

The WSS Machining Advantage: Consistency and Compliance

We are committed to providing machined components that exceed your expectations. Our process is designed to mitigate risk and ensure compliance with the strictest industry standards.

- Mandatory Quality Control: We operate under ISO 9001 standards and mandate Production Part Approval Process (PPAP) documentation for all parts. This ensures that every dimension is verified and documented before the part reaches your assembly line.

- Dual-Footprint Flexibility: We optimize your supply chain by offering U.S.-based machining (Illinois) for immediate needs and lower volumes, combined with our global sourcing network (China, India, Vietnam) for cost-effective high-volume runs.

- Material Versatility: Our skilled machinists are able to work with a wide range of materials, from standard aluminum and steel to exotic alloys and engineering plastics, ensuring we can meet the specific needs of your application.

Partner with a Machining Expert. Request a Quote Today

Secure a partner with the capacity for large parts and the accuracy required for complex geometries. Contact us today to learn more about our machining capabilities and how we can assist with your next project.

Call us directly at 303-284-0540 or submit your project details below.