Structural Integrity Meets Precision Engineering

For heavy equipment, agriculture, and defense industries, structural integrity is non-negotiable. Worldwide Sourcing & Solutions (WSS) provides end-to-end light to heavy fabrication services that combine durable construction with the necessary precision required for complex assemblies.

Our team leverages expertise in advanced cutting and welding to produce high-strength components – from operator cab parts to massive chassis frames – that are built to withstand extreme loads and harsh environments. We ensure your large structural parts maintain the tight tolerances required for seamless assembly.

Fabrication Capabilities: Cutting & Welding

Our fabrication process is a comprehensive system that is fully managed across our U.S. and global facilities. We combine state-of-the-art cutting technology with skilled welding craftsmanship to handle every stage of structural production.

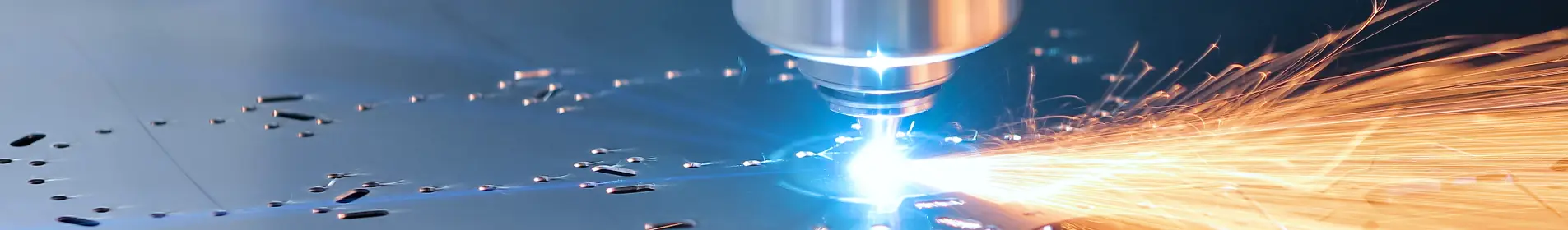

Precision Cutting (Laser & Plasma)

We utilize state-of-the-art technology to produce high-quality parts with intricate designs and strict tolerances. We select the right cutting solution based on your material thickness and volume requirements.

- Laser Cutting: Our capabilities include both CO2 and Fiber lasers, allowing us to work with steel, stainless steel, aluminum, brass, and copper.

- Fiber Lasers: Capable of cutting materials up to 1 inch thick with high speed and efficiency.

- CO2 Lasers: Ideal for cutting materials up to ¾ inch thick.

- Precision: Advanced software allows for complex patterns and intricate designs with highly accurate edges.

- Plasma Cutting: Specialized for thicker, heavier materials and complex components.

- Capacity: We handle a thickness range from 16 gauge up to 2 inches, ensuring the right solution for heavy equipment structural parts.

- Materials: We accommodate carbon steel, stainless steel, and aluminum.

- CNC Control: Our technicians use CNC controls for precise cuts and efficient material utilization.

Welding and Assembly

We are experts in joining metals to create finished weldments with superior strength and consistency. Our experienced welders work with steel, aluminum, and stainless steel using MIG and TIG techniques.

- Robotic Welding: Programmed for high-volume production, our robots perform precise welds in a fraction of the time of manual welding, ensuring a high level of consistency and repeatability.

- Manual Welding: For complex parts that require a hands-on approach, our skilled manual welders produce superior welds that machines cannot easily replicate.

- Accuracy: We rely on precision fixtures and jigs to ensure positional accuracy, which is critical when parts must integrate into large-scale equipment assemblies.

Why Fabrication Matters for Heavy Equipment

Our expertise in light-to-heavy fabrication provides critical benefits for heavy industrial, agriculture, and construction manufacturers:

- Strength and Durability: We guarantee components, such as loader arms and chassis frames, are built using heavy fabrication standards to withstand the extreme dynamic loads and harsh operating environments common in heavy industry.

- Capacity for Scale: Whether utilizing automated laser cutting for intricate brackets or heavy plasma cutting for structural beams, we scale our process to meet your volume demands.

- Key Components: We manufacture vital light fabrication parts (tool brackets, guards, sheet metal housings) and heavy fabrication parts (chassis frames, boom sections, engine mounting bases).

The WSS Fabrication Advantage: Precision and Flexibility

Partnering with WSS means accessing a fabrication channel designed for stability and cost-efficiency, backed by verifiable quality standards.

- Dual-Footprint Production: We offer the best of both worlds. Use our U.S. manufacturing (Illinois) for rapid prototyping, complex low-volume runs, and immediate needs. Leverage our global network (India, Vietnam) for high-volume structural components at a competitive cost.

- ISO 9001 Certified: Quality is not an afterthought. Our fabrication processes are governed by ISO 9001 standards, ensuring weld consistency, material traceability, and dimensional accuracy on every part.

- Single-Source Accountability: By managing the entire fabrication workflow – from raw plate cutting to final welded assembly – we eliminate the risks and delays associated with managing multiple vendors.

- Advanced Technology: Our investment in robotic welding and high-capacity fiber lasers ensures we can meet the tightest tolerances and production schedules of modern OEMs.

Partner with a Fabrication Expert. Request a Quote Today

Don’t compromise structural integrity for precision. Partner with WSS for fabrication services that guarantee both.

Call us directly at 303-284-0540 or submit your project details below to discuss your structural component needs.